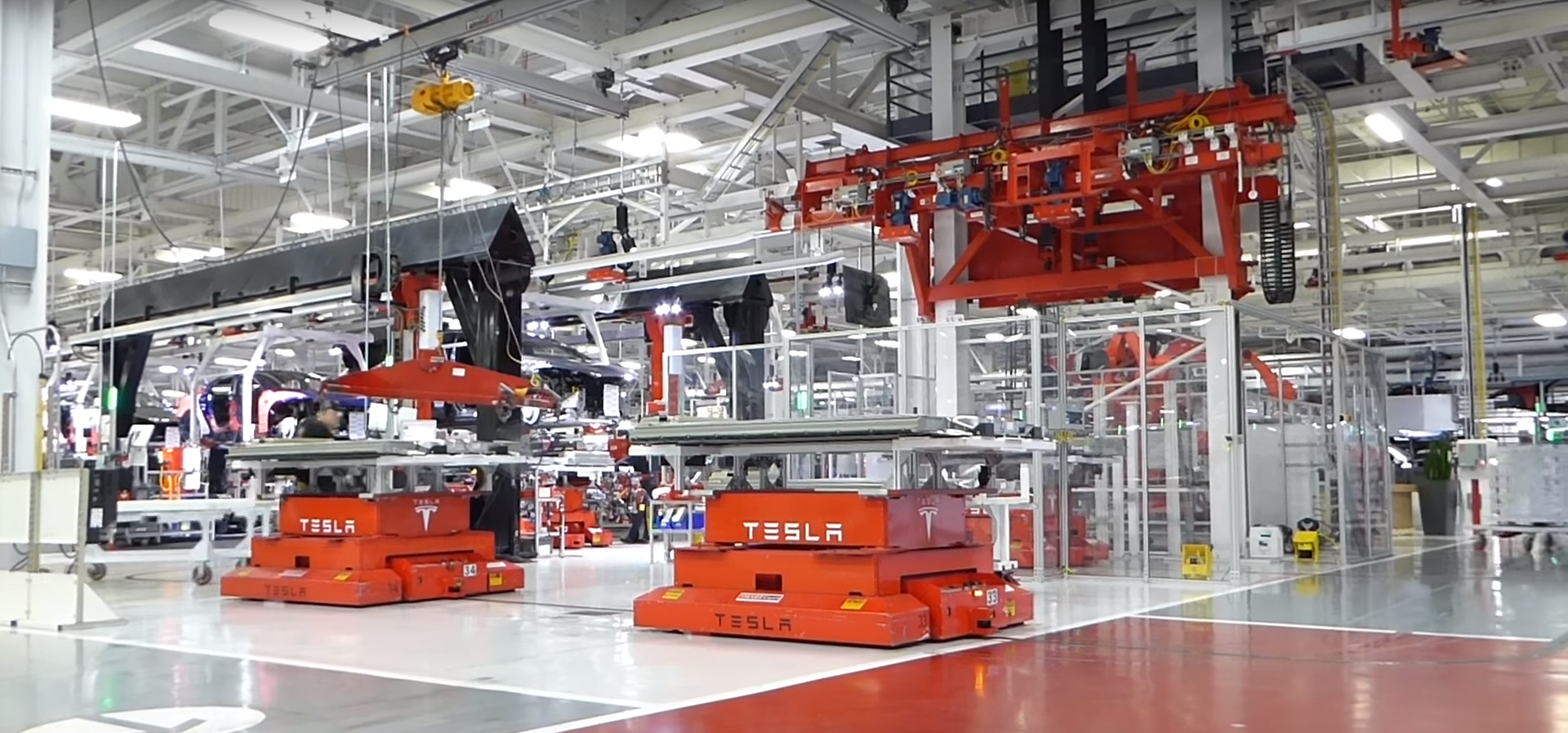

To prepare for Model X production, Tesla this past July halted production at its Fremont facility for two weeks in order to upgrade its assembly lines, modernize its production floor, and of course, ultimately increase overall production.

“This represents the single biggest investment in the plant since we really started operations and enables us for higher volumes,” Tesla spokesman Simon Sproule told Bloomberg earlier this summer. Indeed, the total cost of the enhancements reportedly checked in at a cool $100 million.

Earlier this week, Tesla put up blog post detailing all of the nitty gritty details regarding its somewhat recent factory upgrade.

During the pause in production, we upgraded the assembly line, added capacity to the body shop, enhanced powertrain assembly, and revamped facilities for our employees. The result of this retooling phase, which complemented ongoing upgrade work, is a much-expanded operation that allows us to produce more cars, faster, while increasing automation and providing a more inviting work environment.

…

In the powertrain department, we’ve added conveyors and advanced robots that have given us the capacity to process 1 million battery cells per day, up from 800,000. In body-in-white, we’ve added new welding equipment and improved our production uptime by 5 to 10 percent, thanks in part to a 13-car buffer that guards against bottlenecks. We’ve also added 24 new tire and export docks to the perimeter of the main building, increasing the speed with which we can deliver cars overseas.

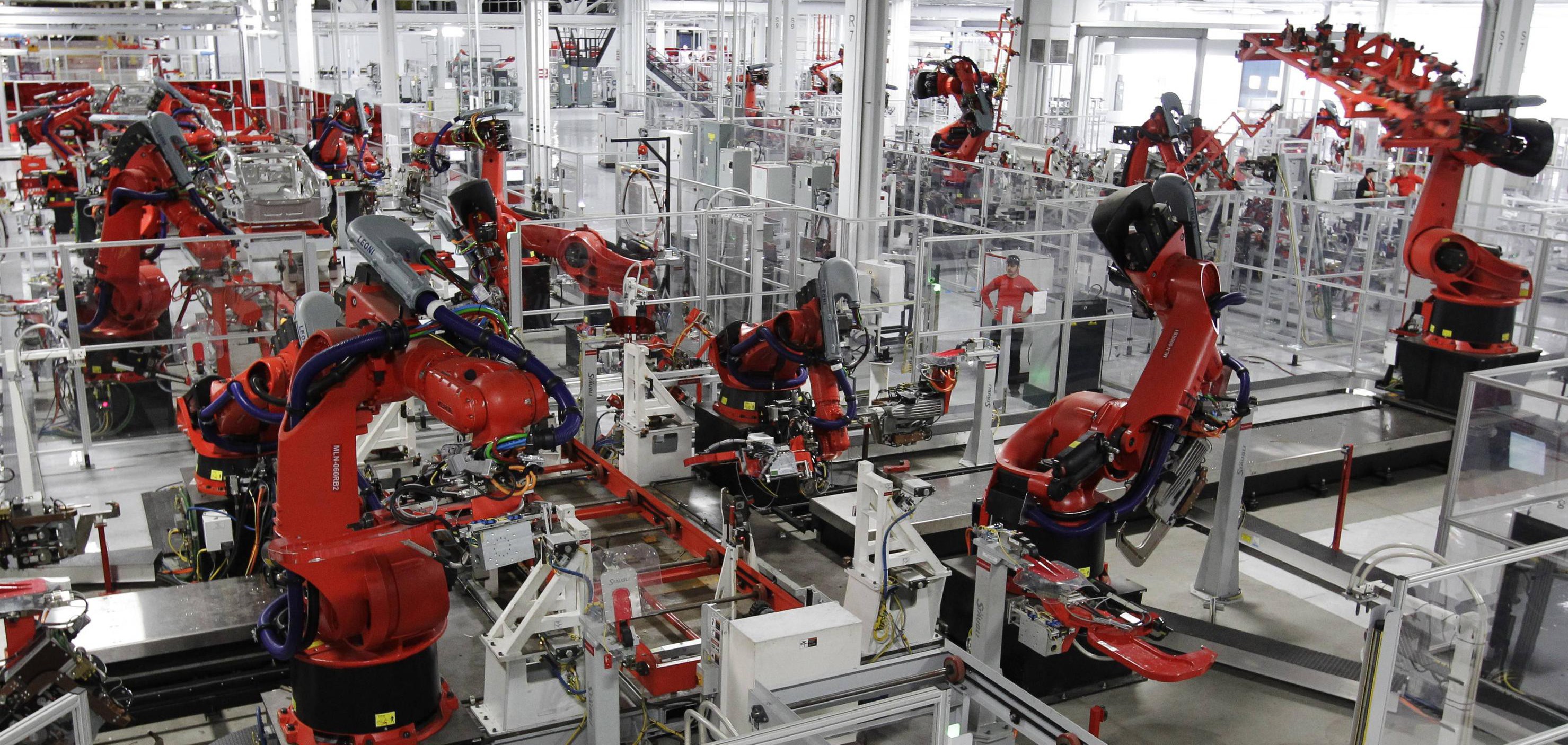

Of particular interest is Tesla’s investment in advanced robots, some of which, the blog post notes, will soon be able to install battery packs on cars. Interestingly, Tesla notes that over the summer, it installed 10 of the largest robots in the world.

What’s more, Tesla has taken to affectionately naming its new in-house robots after X-Men characters.

Rather than refer to these robots by technical descriptions, we named them after X-Men characters. Xavier stands at the entrance to the trim line, lifting cars down to the floor from an electrified rail, while Iceman, Wolverine, and Beast do more heavy lifting nearby. Storm and Colossus can be found at the end of the chassis line, and Vulcan and Havok work as a team to lift cars back onto the rail. To us, these robots are like superheroes, so we figured they deserved superhero names.

Having seen what some of Tesla’s beloved robots can do on various YouTube videos, it’s hard to disagree with that. Interestingly, Musk noted during Tesla’s most recent earnings conference call that it’s often “way harder to make the machine that makes the machine than it is to make the machine in the first place.”

The entire post is well worth a read and is chock full of interesting information (and videos!) about Tesla’s recent factory upgrade.