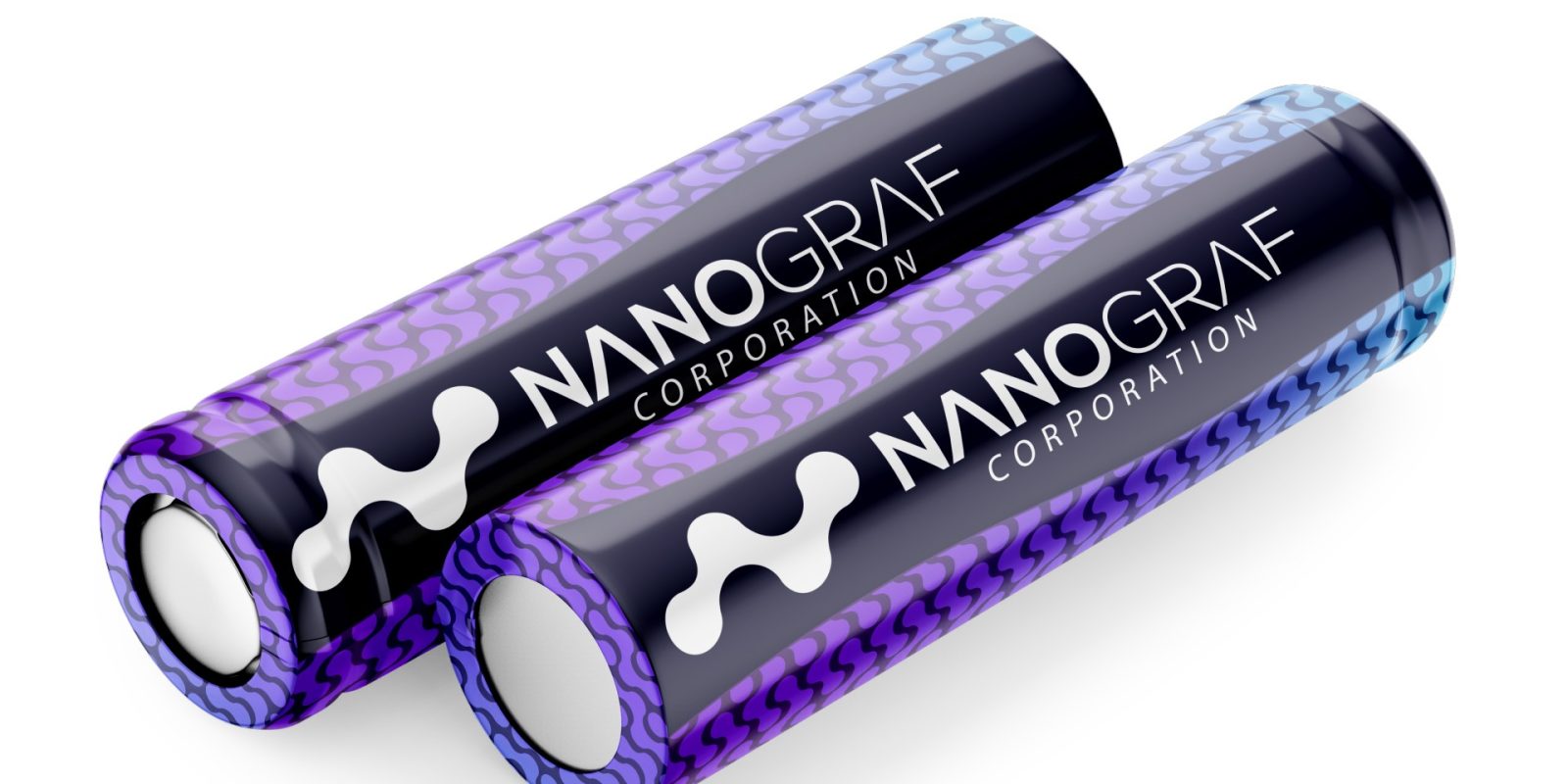

NanoGraf to launch US’s first large-volume silicon oxide factory

Chicago-headquartered NanoGraf Technologies, which claims it has enabled the world’s most energy dense 18650 lithium-ion cell, today announced that it will open the first large-volume silicon oxide factory in the United States. At peak production, NanoGraf will produce 35 tons per year.

Expand Expanding Close